Code : SKP-004

Brand name : SAIKOPACK

Price : Contact us

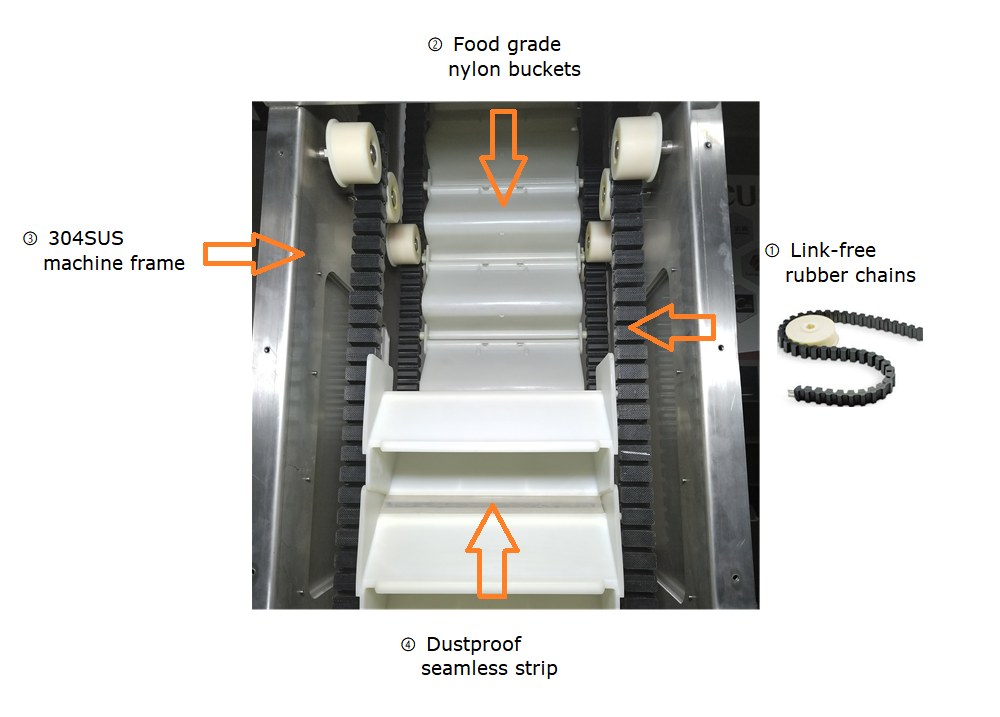

This new design bucket elevators feature a rubber chain system that make them cleaner, quieter, and more reliable than conventional metal chain elevators.Capable of running in extremely harsh and dusty environments, the systems are also vibration-free, abrasion-proof.

IN FOOD INDUSTRY:

Particularly in the food industry, the advantages of continuous bucket conveyors and pendulum bucket conveyors are clear to see. By using original rubber chains, no lubricants are required that could contaminate the conveyed materials.

The casing can be designed in accordance with the highest hygienic requirements, such as with a tubular framework without horizontal surfaces and dead spaces.

On the pendulum bucket conveyors, the buckets can be removed without tools in a single action to clean them externally. Automatic cleaning stations can also be supplied for cleaning the buckets in all series.

Detectable buckets offer the ability to increase your product safety.

IN NON-FOOD INDUSTRY:

With link-free original rubber chains, continuous bucket and pendulum bucket conveyors have proven themselves in the food and non-food area. Even abrasive materials and those causing wear can be conveyed with ease.

Technical Parameters:

|

Model |

Rubber chain bucket conveyor |

|

Bucket type |

Food grade ABS |

|

Bucket Volume |

3.7L |

|

Machine Height |

3896mm or customized |

|

Machine frame |

304/316 stainless steel, carbon steel |

|

Operation type |

Continuous/Pendulum |

|

Speed |

Adjustable |

|

Production Capacity |

10-30 m3/h |

|

Voltage |

220V/380V, 50HZ/60HZ, 0.75KW |

Features:

1.Buckets can be removed without tools

2.Very stable running

3.High conveying capacity

4.Perfectly suited for abrasive products

5.Dust-tight version available

6.CE certification

7.ATEX version available

8.Custom size design possible

9.Multiple drop-off points possible

10.For weighed or counted products, the bucket position can be determined reliably at any time (no elongation of the rubber chains!)

Our Service

Hotline