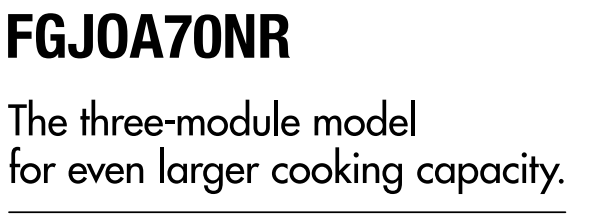

Code : Long Series

Brand name : FUJIMAK

Price : Contact us

We provide excellent cooking capability and high-quality specifications for an extensive range of industries, including food processing.

Our Long Series provides higher per-hour cooking capability with an extended oven heating length.

Our ovens are used in the large-volume cooking facilities of school and office catering services as well as in various food processing industries, including those producing meat products, prepared dishes, confectioneries, bread, and seafood.

Our ovens are used in the large-volume cooking facilities of school and office catering services as well as in various food processing industries, including those producing meat products, prepared dishes, confectioneries, bread, and seafood.

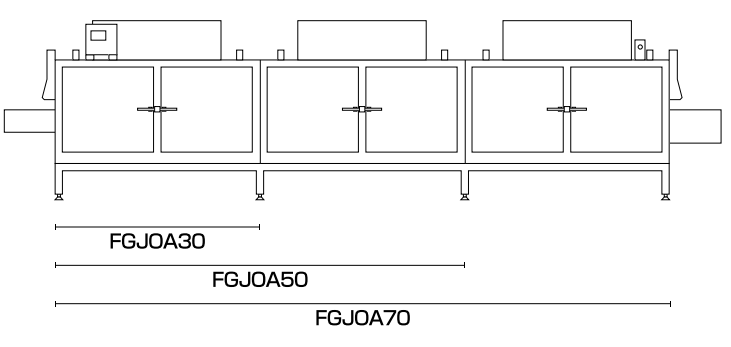

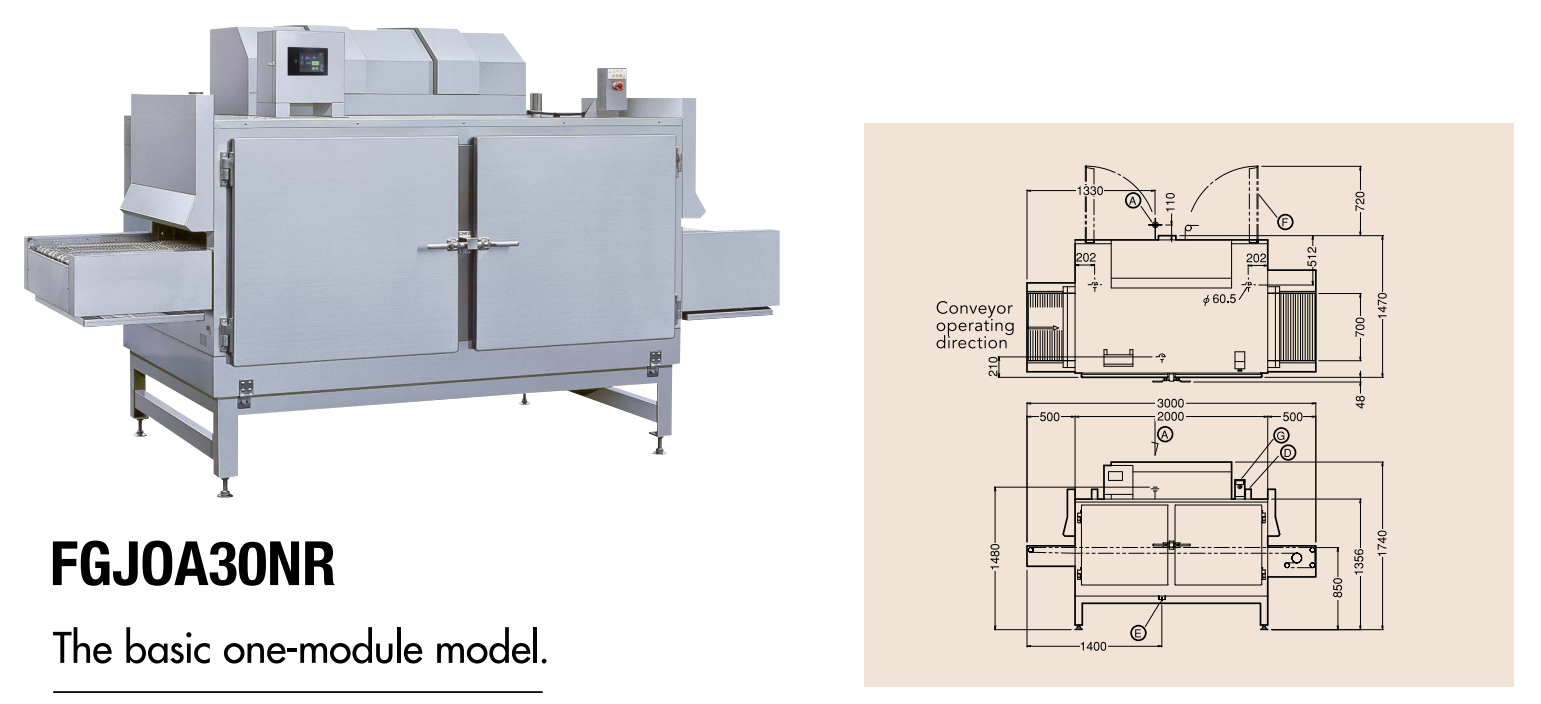

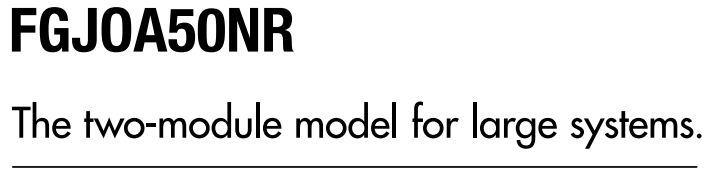

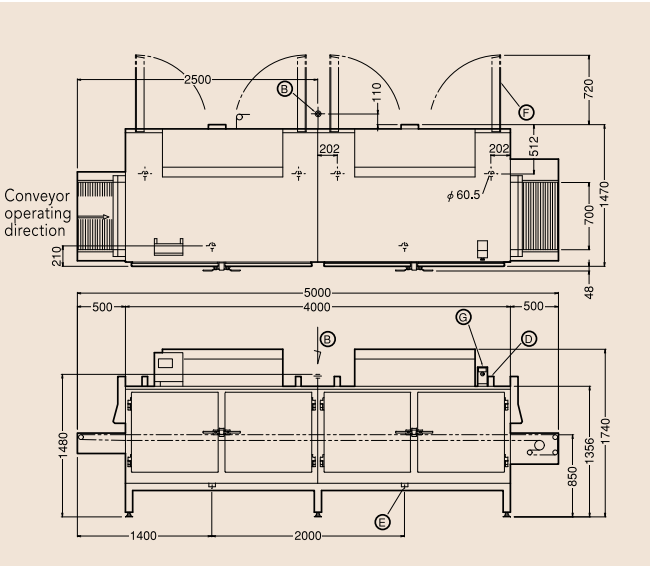

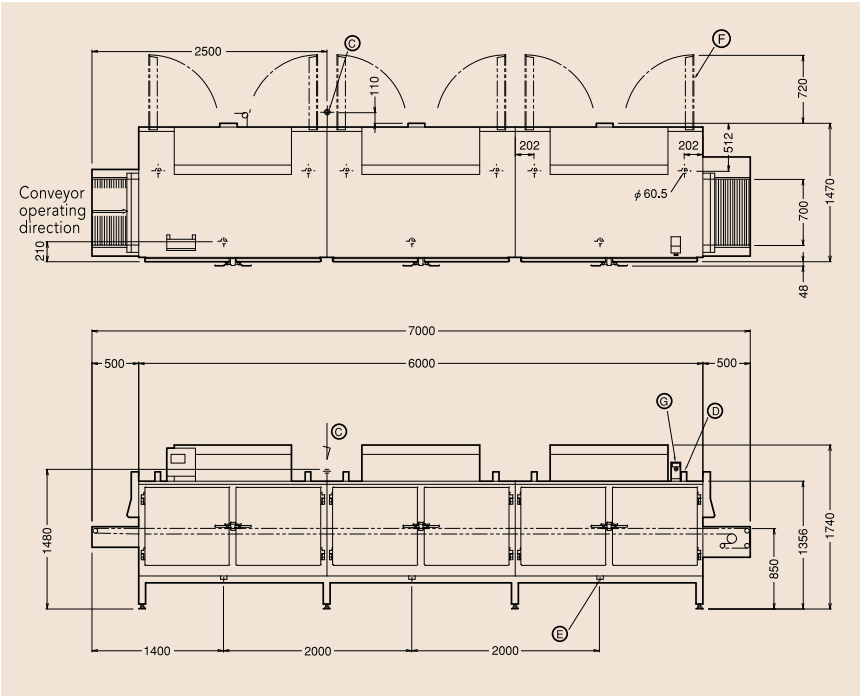

Specific cooking parameters can be set for each chamber module. Parameters can be set in two zones in the FGJOA50 model and three zones in the FGJOA70 to achieve the ideal product finish.

Products specialized for a wide range of large-volume cooking with high processing capability

Steam function for better flavor (steam models)

Steam models (noted with an "S" appearing at the end of the model name) ) can be connected to an external steam generator to cook with hot air containing steam. The steam inlet amount can be adjusted to three different levels, making it possible to apply the optimum amount of steam to specific items.

(Models do not come with the steam-generating function built in. A separate steam genernator is required.)

Adiustable airflow to meet cooking requirements

The adjustable three-level airflow makes it possible to use air impingement heating at the airflow level that is appropriate for the food being prepared.

Adiustable conveyor opening height

Shutters are provided at the conveyor entrance and exit. Adjusting the shutters' height to suit the food being prepared can prevent heat from escaping the oven. In addition, the height of the openings can be raised without replacing any of the finger nozzles that eject heated air or conveyor opening parts, making it possible to cook foods of greater thickness.

(Standard: 85-mm opening; adjusted: 125-mm opening)

Two conveyor types to meet specific needs

Net conveyor

Oven pans, flat grids, and actual food items can be placed directly on this type of conveyor.

Bar conveyor

A bar conveyor is the best type for carrying oven pans and flat grids.

Exceedingly easy cleaning with water

Cleaning doors provided in the rear make cleaning the chamber easy.

.png)

.png)

*Power source: 3P 200V (Local voltage is available) *Range cooking temperature settings: 170-350 0 C *Range of conveyor speed settings: 2-30 minutes

*A model number ending in "S" indicates a steam model

*The letter "L" or " R" appearing in a model number respectively indicates the conveyor belt direction. L indicates a model with a left-hand conveyor outlet when viewed from the unit s front and R a model with a right-hand conveyor outlet.

Tray Loader System

The system automatically feeds and removes oven pans/grids during time-consuming large-volume cooking, thus saving labor.

The system automatically feeds and removes oven pans/grids during time-consuming large-volume cooking, thus saving labor.

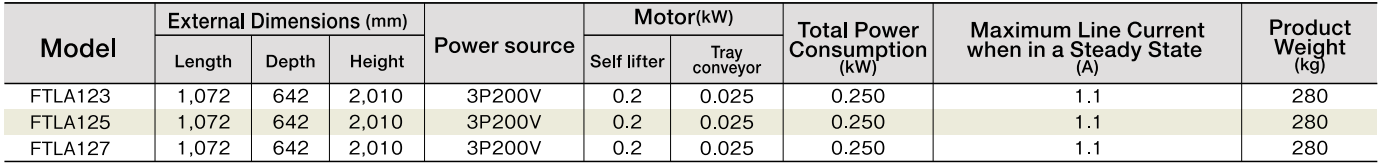

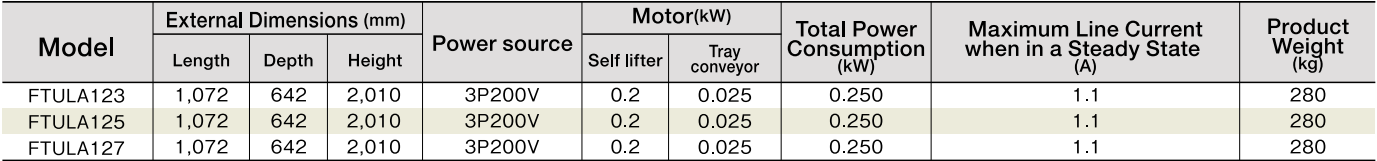

Tray loader

Tray unloader

*Number ending in "3": For the Jet Oven Long Series 30 Number ending in "5": For the Jet Oven Long Series 50 Number ending in "7": For the Jet Oven Long Series 70

Tray conveyor speed: Synchronized with Jet Oven Applicable tray dimensions : 650(W) X 450(D) X 25(H)mm

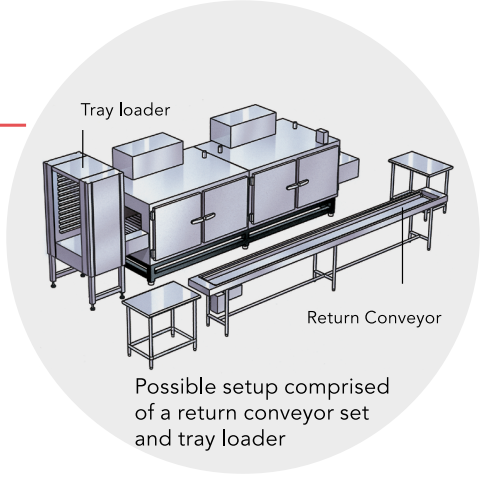

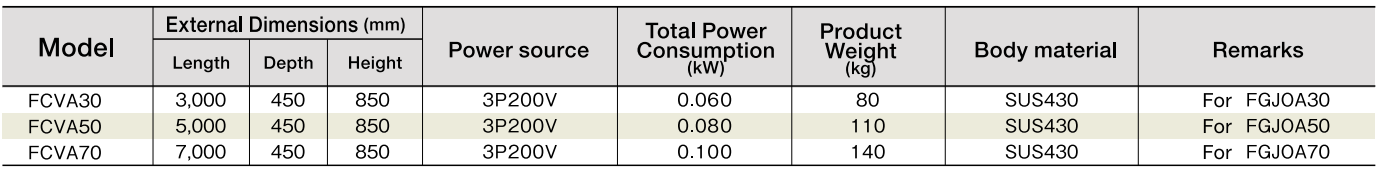

Return Conveyor

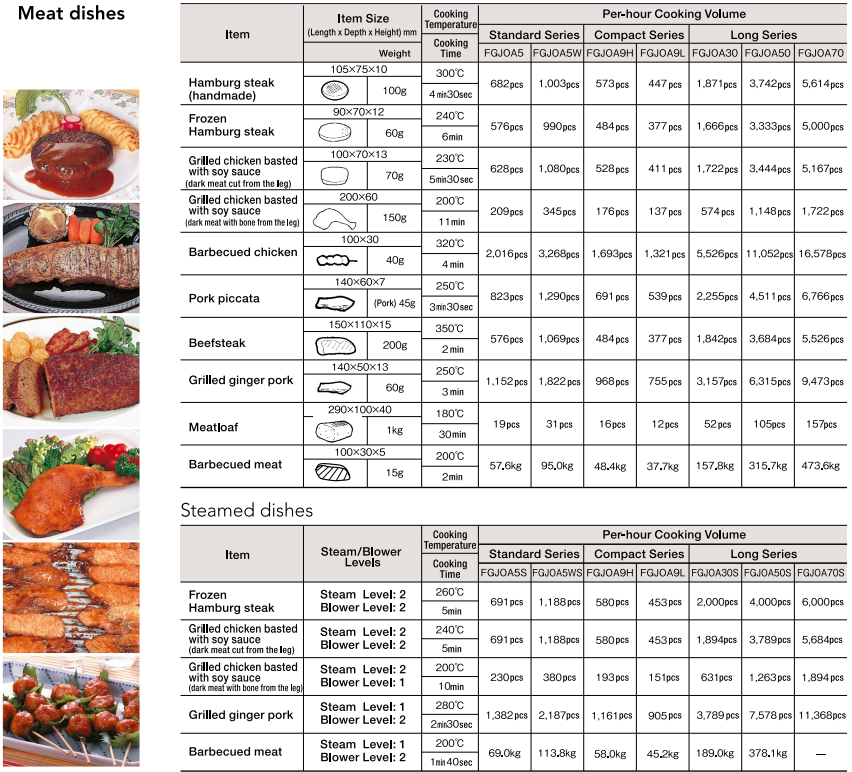

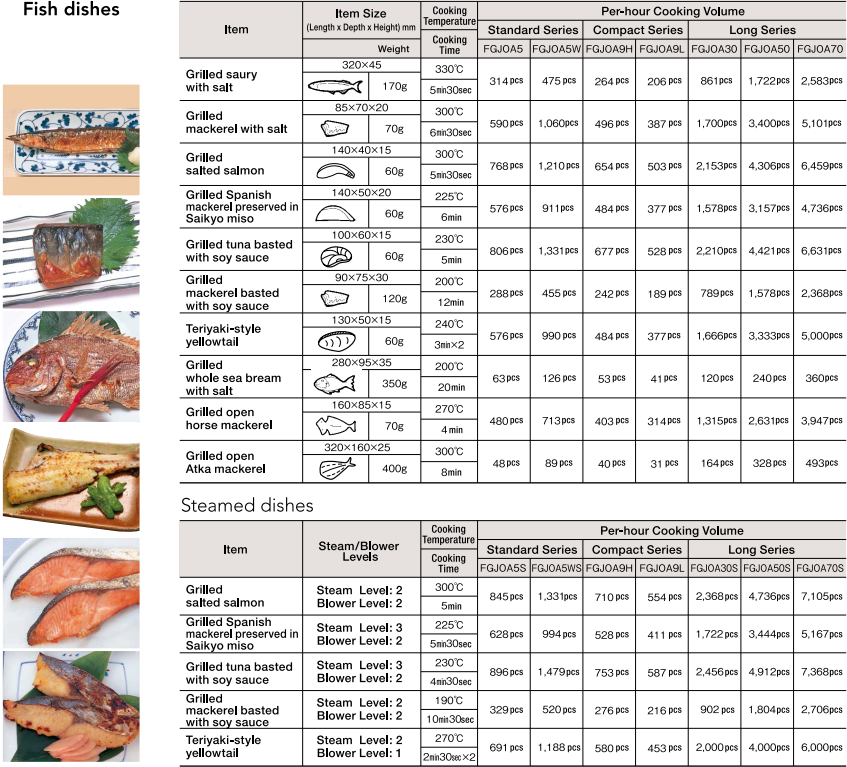

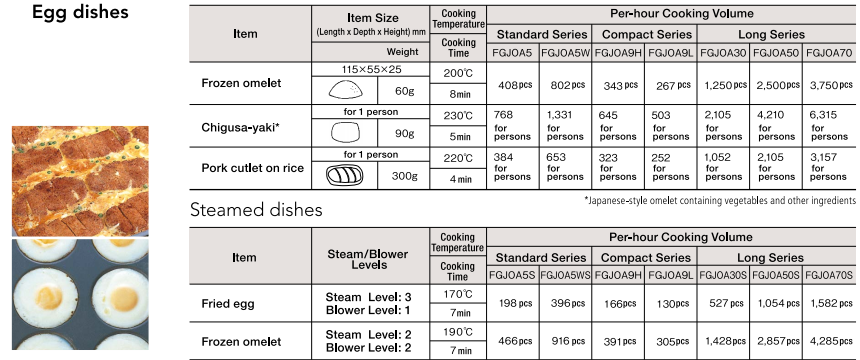

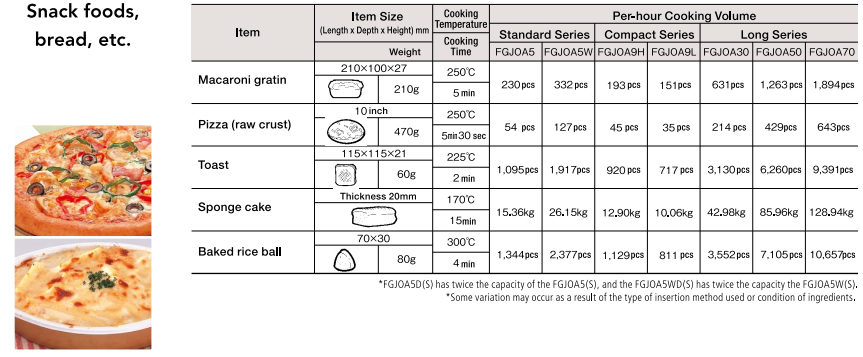

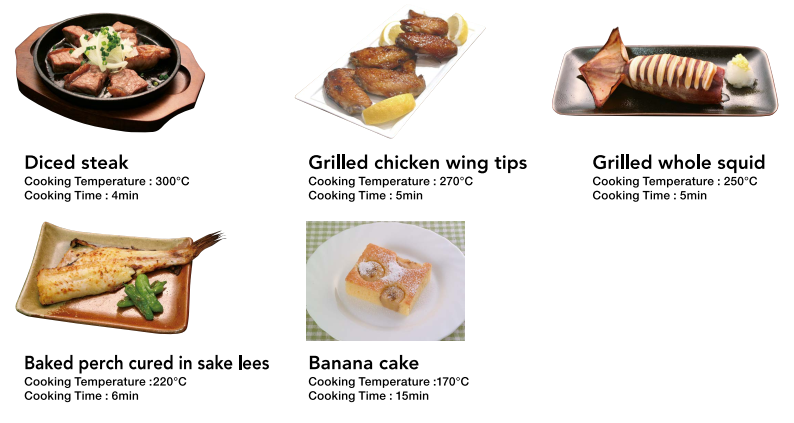

Standard Series / Compact Series / Long Series Cooking Examples

*FGJOA5D(S) has twice the capacity of the FGJOA5(S), and the FGJOA5WD(S) has twice the capacity the FGJOA5W(S). *Some variation may occur as a result of the type of insertion method used or condition of ingredients.

Standard Series / Compact Series / Long Series Cooking Examples

Compact Series Cooking Examples

*Some variation may occur as a result of the type of insertion method used or condition of ingredients.

Hotline