Drying process is heated evenly, creating excellent quality

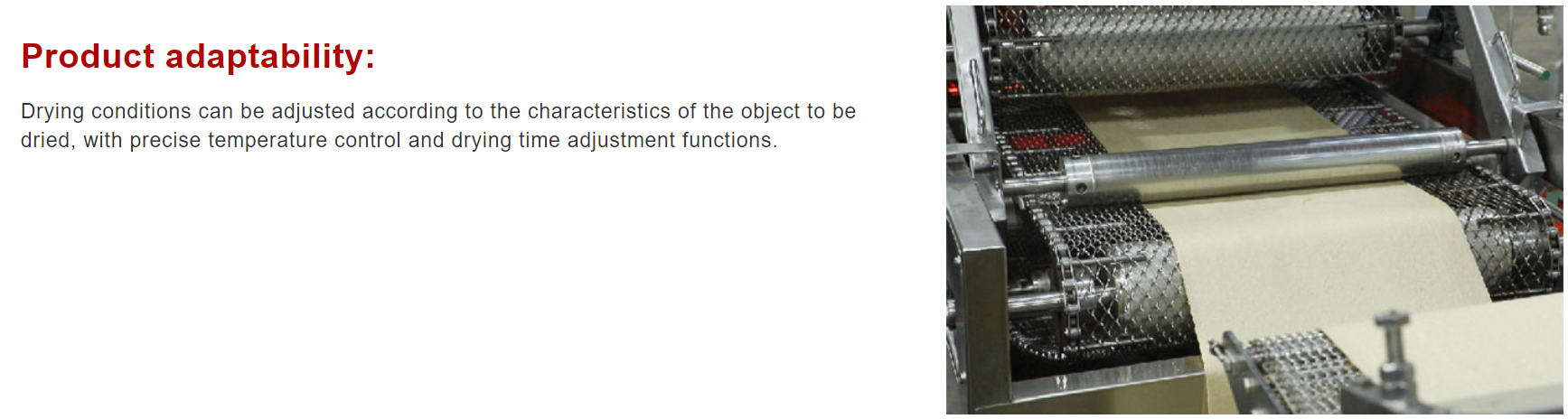

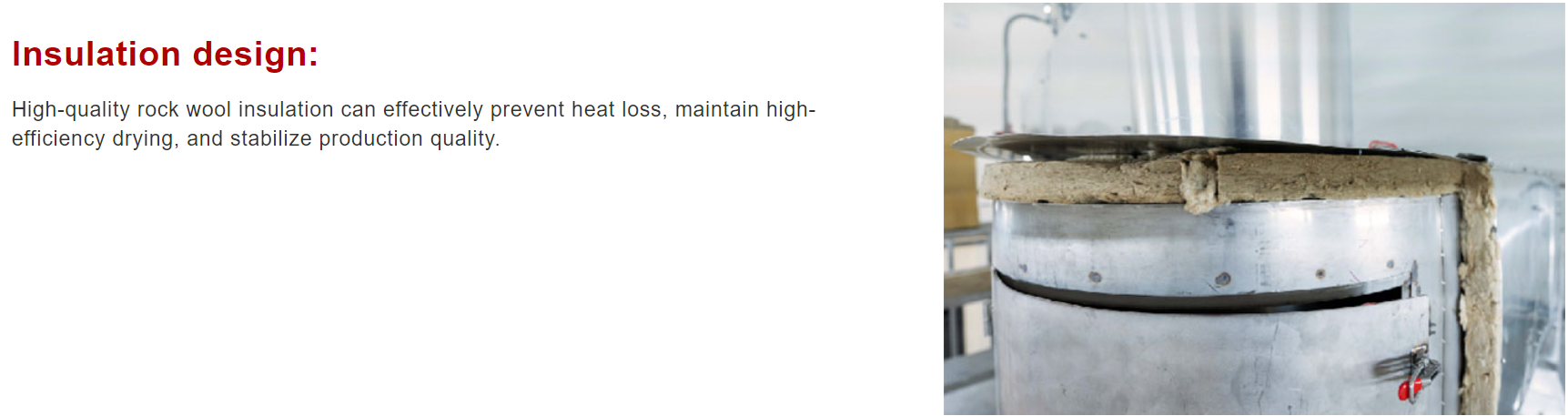

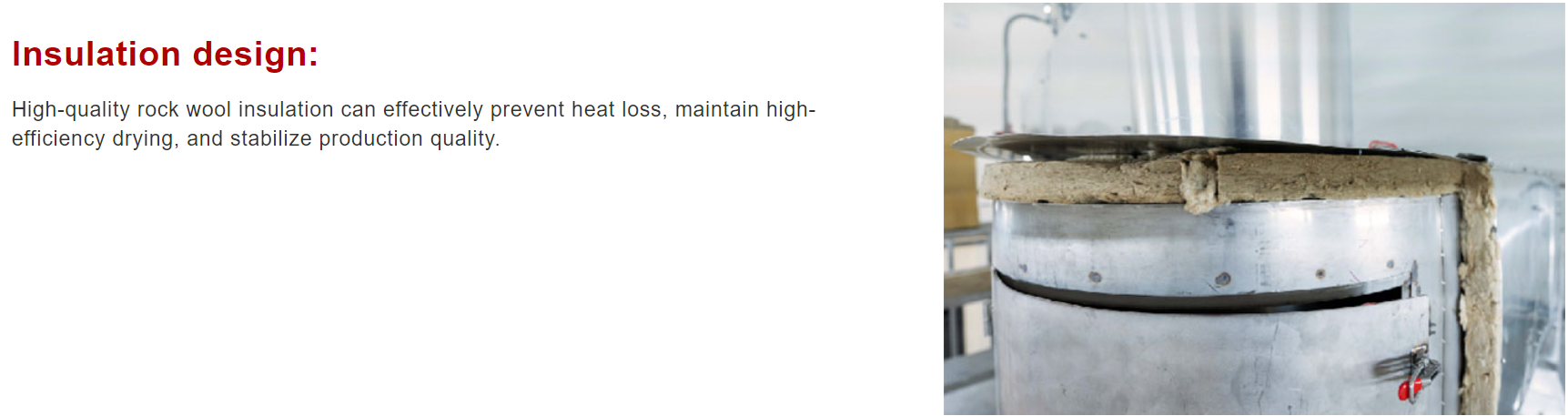

The baking heating box adopts high-quality insulation materials and design to ensure that high-temperature heat energy is not easily lost during the production process, effectively improving thermal energy efficiency and achieving high-quality production results with the result that the dried materials are heated evenly.

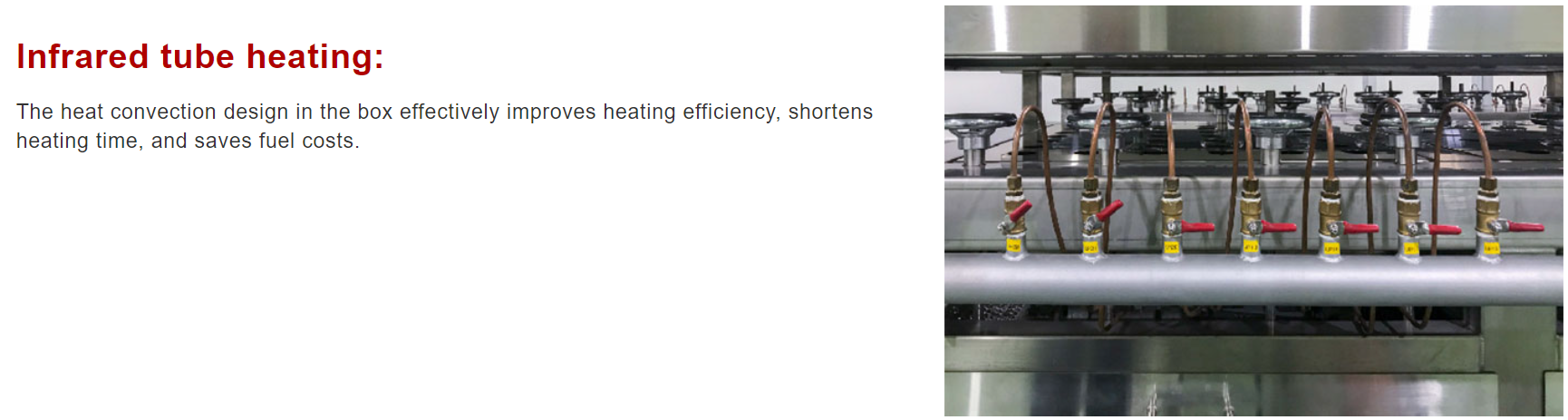

The Infrared Tunnel Oven is an efficient, advanced heating solution that utilizes infrared technology to achieve fast, even heating. The oven can be designed to connect front and rear equipment to achieve continuous production and provide high-quality drying processing for various products.

- Increased Productivity: Faster heating times lead to higher throughput.

- Cost-Effective: Reduced energy usage lowers operational costs.

- Quality Assurance: Infrared heating can improve product quality.

- Versatility: Suitable for a range of materials and applications.

- Eco-Friendly: Lower energy consumption reduces environmental impact.

Applicable areas:

Food processing | Electronic devices | Metallic materials | Biopharmaceuticals

Your best Infrared Tunnel Oven Solution

- Reduced Processing Time: Solves the issue of slow production rates.

- Energy Savings: Addresses high energy costs in manufacturing.

- Consistent Quality: Eliminates inconsistencies and defects in products.

- Space Optimization: Compact size helps in efficient use of manufacturing space.

- Adaptability: Its versatility helps businesses adapt to varied manufacturing needs.

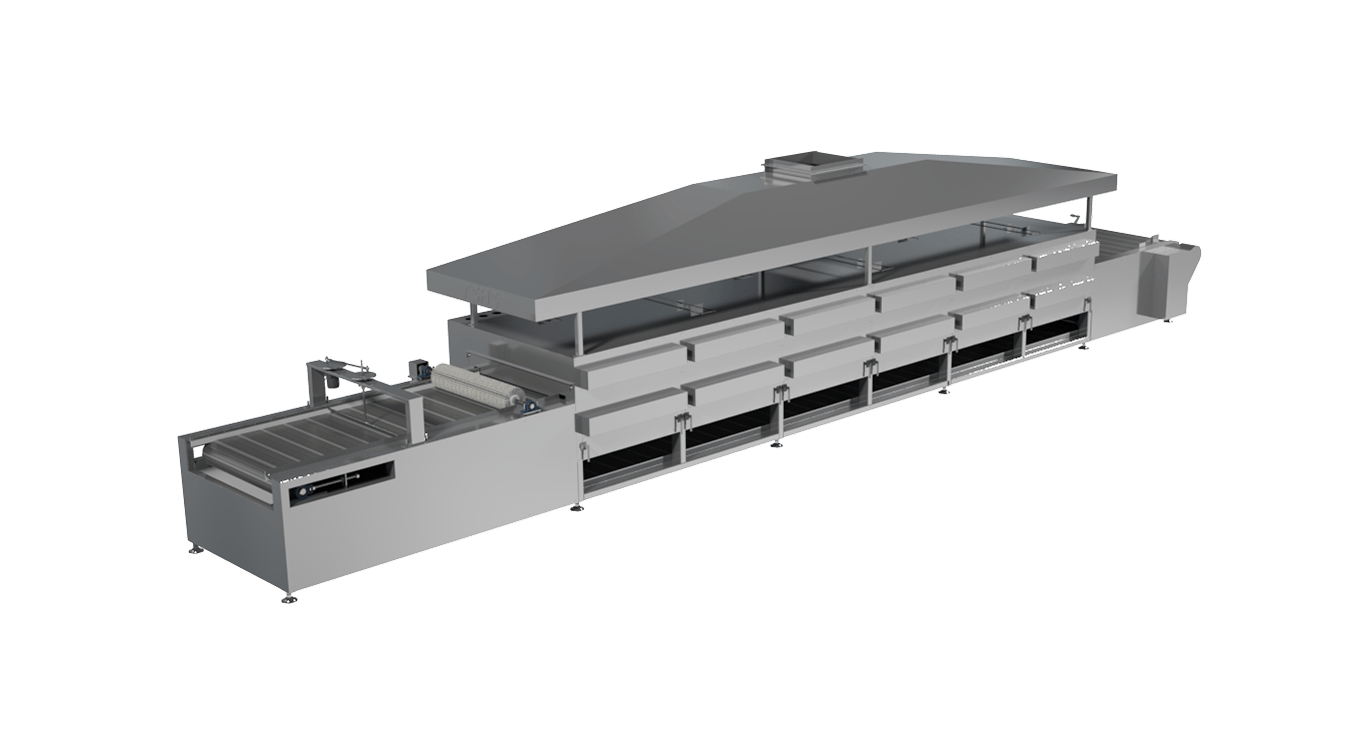

Product 3D drawing

Reliable tunnel oven, widely used in various industries

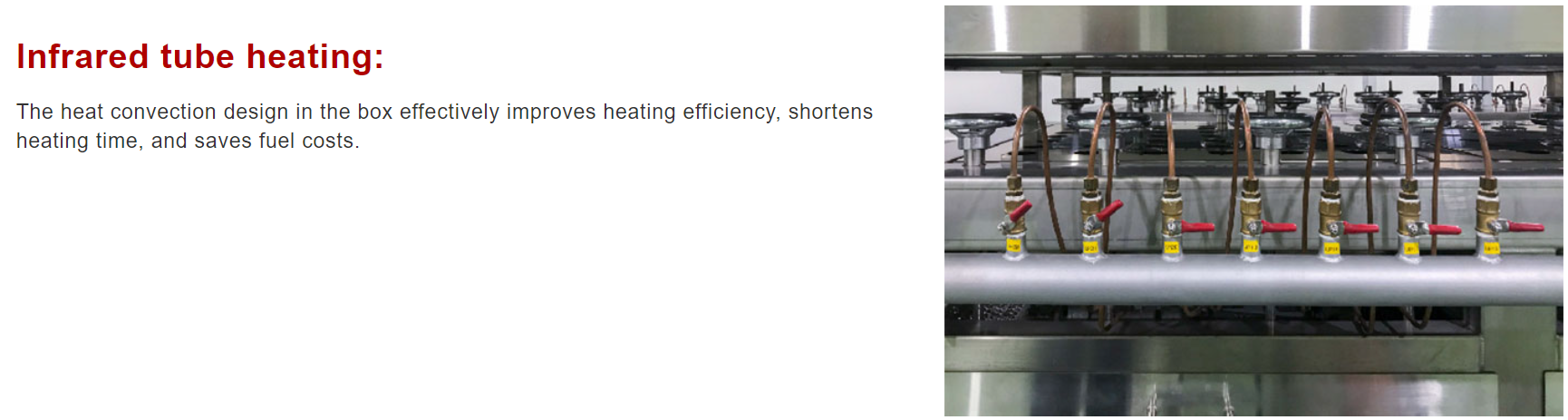

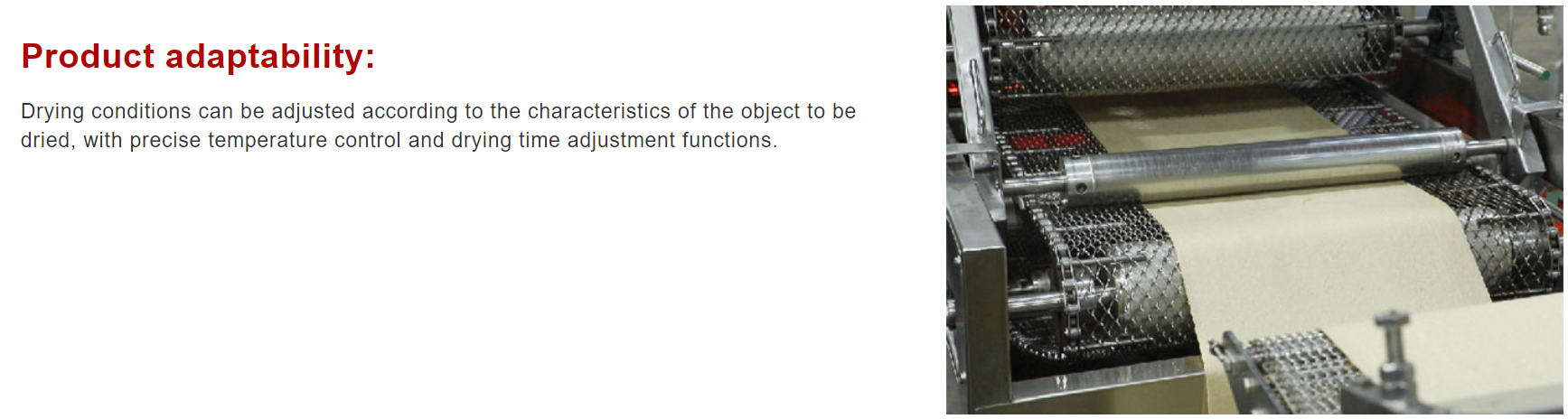

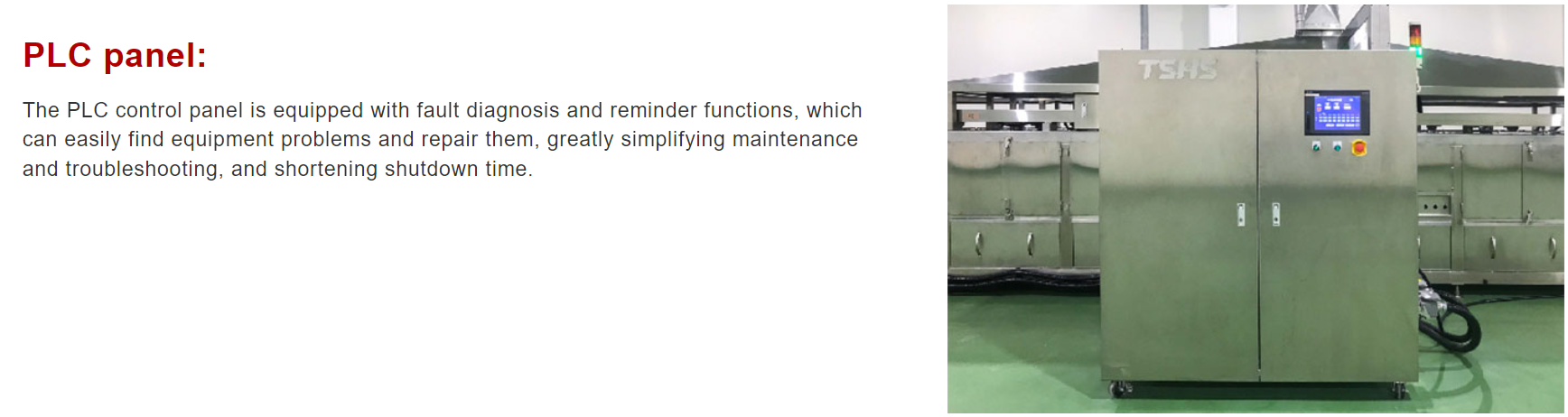

Features of industrial tunnel oven

Application

Food processing:

Tunnel ovens are commonly used in the food processing industry to bake bread, biscuits, crusts, rice crackers, fish shreds and other snack foods. Its rapid and even heating properties ensure product quality and taste.

Ceramics:

In the production of ceramics, tunnel ovens are used to bake and sinter the ceramics to increase their hardness and durability.

Electronics industry:

Tunnel ovens are used in the electronics industry for welding, curing and sintering of electronic devices to ensure the performance and lifetime of electronic devices.

Chemical industry:

In the chemical industry, tunnel drying ovens can be used for drying, hardening or decomposition of various chemical substances.

Coatings and paint applications:

It is the application of paint coatings to the surface of objects, commonly used in the coating of automobile manufacturing, roll paper, and glass, etc. When removing the water and solvent simultaneously, the coating material will harden to form a solid film, ensuring its gloss and durability.

Plastics and rubber industry:

In the plastics and rubber industry, tunnel ovens are often used in the drying and hardening process of materials.

Food processing: Rice crackers, Cake crust, Shredded fish, biscuits, Baking, roasting, and drying various food items

Chemical industry: Chemical materials

Industrial Manufacturing: Curing coatings, adhesives, and finishes

Textile Industry: Drying and processing fabrics

Plastics and Polymers: Preheating and thermal shaping

Electronics: Component soldering and circuit board processing

Other industries: Rubber materials, plastic products, and drying of mineral soi