Code :

Brand name : Tsunghsing

Price : Contact us

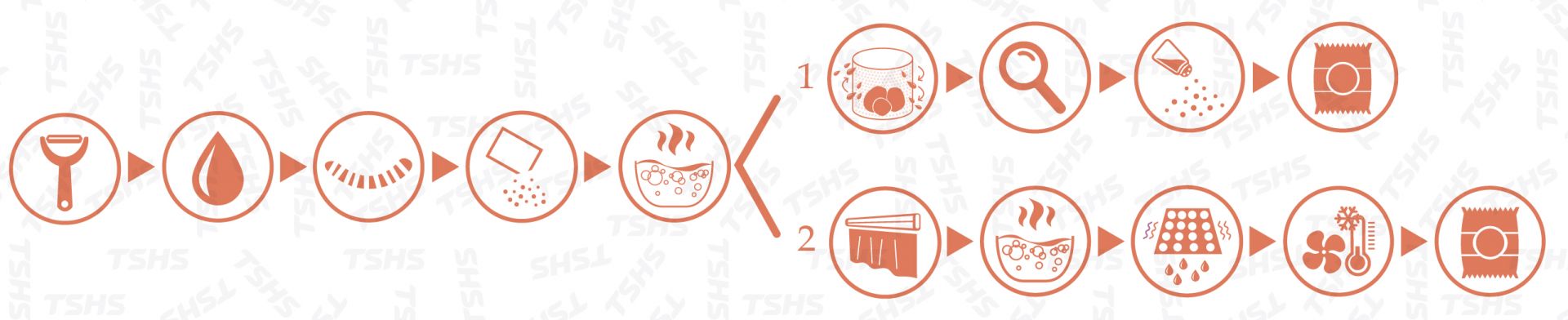

The Banana Chips Production Line uses banana as the raw material which is easy to obtain. It becomes the tasty snack and suitable for all ages after being washed, sliced and deep fried.

The raw material of the Banana Chips Production Line is fresh banana, and the banana aroma and taste crispness are optimized after the frying process. Therefore, the Banana Chips Production Line uses this feature to produce the banana chips by peeling the banana, frying and seasoning.

After being peeled, the banana will be sticky due to the feature of itself. Therefore, after peeling, it needs to be washed and then sliced. Generally, the slice thickness ranges are from 3 to 5 mm. Different slicers can be used optionally according to customers' needs.

After the banana is sliced, it can become semi-finished banana chips. After frying, it can optimize the aroma of the banana chips and make it taste crispy.

After frying, different seasonings can be made according to the needs of the customer's market. The following can be divided into the following two types:

1. Customers may just need the simple seasoning powder to taste, it is recommended to use the flavor powder sprinkler, the liquid sprayer and the rotary seasoning drum to make the seasoning powder fully adhere to the product.

2. Customers can also screen the fried banana chips first, then wrap the fried banana slices in sugar, and then fry the second time to obtain the fried banana chips.

raw material: Peeling→

Green bananas are manually peeled after being sent to the factory.

(It's easy to cause lots of damage during the process of mechanical peeling because of the different size of bananas. )

Discharge:banana chips→

actual production of high yield fried banana Chips

Hotline