Code :

Brand name : Tsunghsing

Price : Contact us

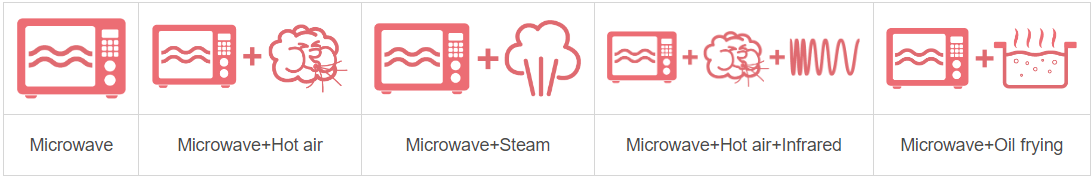

The heat conduction of the hot air dryer to the product is from the outside to the inside. However, the microwave technology can make the water molecules friction and vibration inside and outside at the same time of the product. Which can generate heat energy evenly. so that the heating speed becomes faster. So mixed microwave function is compared to general hot air drying. The drying time would be shortened by about half.

The advantages of microwave function have improved heat efficiency, energy saving, promote production efficiency, rapid heating, uniform heating, and upgrade product quality...etc.

Microwave drying technology is widely used in food industry now. For example agricultural products processing, chemical materials, medical materials and biotechnology industry, cloth textile industry, ceramic industry, natural rubber processing, laboratory analysis... etc. Moreover, the microwave function is suitable for applications that increase the added value of finished products or products with high economic value.

Rubber:Industrial continuous dryers for rubber are often used for heating and drying rubber materials. They can be used for injection molding. Suitable for solid tires and shock-proof rubber, fireproof rubber, rubber polymerization heating... and other rubber materials that need to be dried.

Food:Continuous hot air dryers are often used for food need to be dried or dehydrated. The purposes of food drying are food maturation process, food sterilization and mold prevention, tea de-greening and drying, raw material drying, and food drying processing for nuts, coated peanut, almonds, and roasting beans. And oven drying for medical drugs and Chinese herbal medicines, food unfreeze, meat thaw with low-temperature drying, or drying for snack foods and instant foods ...etc.

The continuous belt dryer equipment of Tsung Hsing is made of stainless steel, which can meet the food-grade hygiene standards.

Chemistry:Continuous hot-air dryer with microwave function is often used in the chemical industry for plastic, resin foaming, iron products drying and hardening, and kiln ceramic molding...etc any chemical reactions that need to heating, drying, dehydration, and molding.

Lumber And Paper:Wood dryers are often suitable for processing of wood products which need heating and drying. Also used the drying process of stick wood plywood, insecticidal treatment or moisture dehydration of wood. And the drying requirment in the production process of paper/pulp/carton.

Fiber and Print:Continuous dryers for cloth fiber/pigment are used dehydration and drying process for heat treatment and extension treatment of synthetic fibers and nylon materials and water paint dyeing... etc.

Others:The continuous industrial hot air circulation dryer can be suitable for any processes that require drying, dehydration, baking, and sterilization products. Such as: soil sludge sterilization , or application of medical materials and biotech products...etc.

Hotline