Infrared dryer drums use radiation to transfer heat to the targeted object, eliminating the energy loss in traditional indirect heat transfer method using hot air. This technic save energy, heat up objects quickly, and shorten the drying time, thereby improving product quality and productivity. The rapid crystallization of materials is advantageous to the scheduling of production lines. The material linger time is adjustable according to the transmission speed of the drum to find the most suitable crystal drying time. Moreover, the conveying speed of the feeding screw is also adjustable to regulate the processing capacity of the machine.

1. Infrared radiant heater (heat lamp)

2.Spiral feed rotating drum

3.Material feed measuring system

4.Air delivery device

5.Electric air temperature control and detecting system.

Material mixes as it moves through the dryer rotating at 1-5 RPM causing very little powder in this first in/first out system.

The infrared equipment incorporates an air cooling device that protects the infrared tubes and prevents plastic particles from sticking. The air shield also extends the working life of the infrared tubes.

An infrared temperature sensor reads the exact material condition information. The user may select a human machine interface control (HMI) or a conventional control panel.

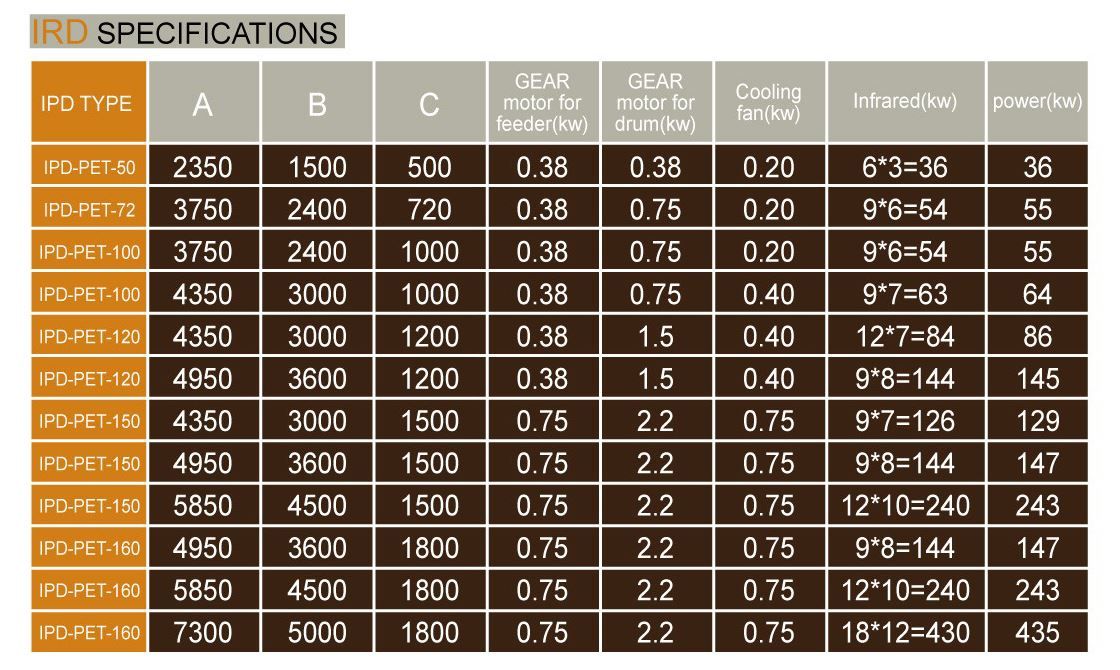

Specifications

Hotline