1. The raw material is easy to get: Corn Grit + Water were pressurized heat through friction, then shaped and extruded by the air ingress.

2. Simple productive process: Shaping and extruding → Frying → Seasoning, then packaging for sale.

3. Easy to control and economize manpower by automatic production line.

4. Stable quality of the Corn Curl Product from integrated production, and it compliances the law on food hygiene.

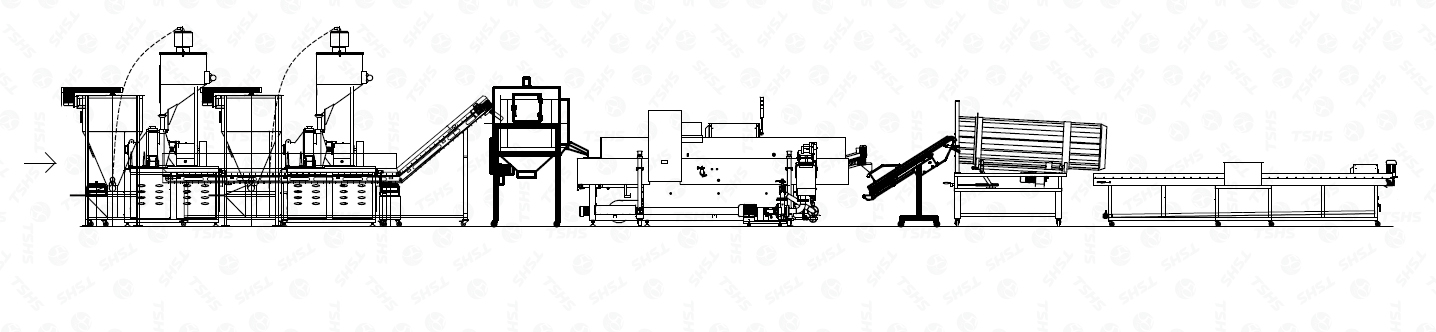

Mixer → Feeder → Extruder → Screening → Quantitative Feeding → Oil Fryer → Seasoning → Cooling Conveyor → Packing

Raw Material Mixing and Humidification: For the humidity of general commercially available corn flour raw materials are about 12~13%, the raw materials need to be uniform mixed with water to reach the humidity 15~16%.

Vaccun Feeding Machine: The humidified mixture of good corn raw materials, sent to the extruder.

Extruder: Mixed corn grit, which is sent from the extruder bucket to the composite millstone by screwing through the extruder, after molding the product is semi-finished products.

Screening machine: The semi-finished products will be the initial screening, will be too small semi-finished products in this first screening out to stabilize the quality of finished products after frying.

Quantitative Feed Machine: The use of vibration to semi-finished products into the frying machine in order to avoid frying due to the amount of material into the oil temperature.

Continuous frying machine: The selected corn strips are sent to the fryer for frying, and the fryer of TSHS has the characteristics of two highs and three savings which can be stabilized early and filtration systems designed for agitating blade corn oil plus strip, so that products can reach 200 to 300 kg/ hr of the production capacity. The general temperature setting is about 170-190 ° C when frying, and the frying time is from 40 to 90 seconds, depending on the raw materials.

Conveying process of Corn Curl(Kurkure, Cheetos) followed by seasoning system after frying.

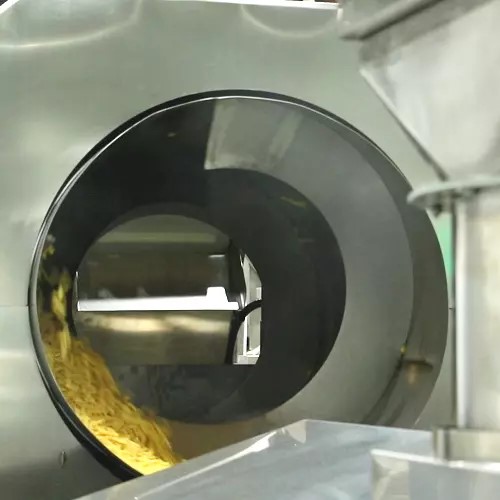

Rotary Seasoning Drum: Modest seasoning after sent the fried Corn Curl to the rotary seasoning drum according to local taste. If the customer only needs simple seasoning powder seasoning, it is recommended to use the flavor powder sprinkler, the liquid sprayer and the rotary seasoning drum to make the seasoning powder being attached to the product. If the customer needs to mix the seasoning powder with the seasoning liquid, it is recommended to use the spray mixer and the mix of barrels, so that the seasoning liquid can be attached to the product.

Cooling Conveyor: After the seasoning of the product temperature is still about 70 to 80 degrees, the use of cooling conveyor can effectively cool the product temperature (about 40 to 50 degrees) to facilitate the back into the packaging machine, and can use the cooling conveyor to do product testing, here With the artificial sale of poor products will do the final screening shave to get the best product.

Hotline