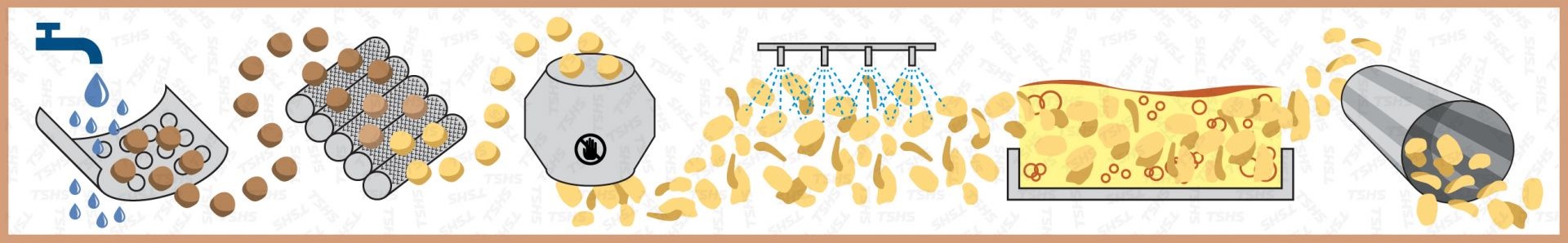

The Potato Chips Production Line of THSH is automatic, which is easy to operate and economizes manpower. The equipment is made of stainless steel, which is easy to clean and meets hygienic standards. Using fresh potatoes as raw materials, the whole process of washing, peeling, slicing, washing, de-watering, frying, seasoning and other steps to make delicious potato chips. The crispy taste with different flavors and packaging, suitable for all ages, and it is one of the most popular snack food in the world.

The Potato Chips Production Line of TSHS, with the continuous fryer as the core, is equipped with conveyor, washing m/c, peeling m/c, slicers, washing m/c, de-water device, seasoning device…etc, combined into automatic production line, which economizes manpower.

Capacity

- 100kg/hr (PC100)

- 300kg/hr (PC300)

- 500kg/hr (PC500)

Features

- Having 100 kg/hr, 300 kg/hr, and 500 kg/hr optional capacities according to the requirements.

- PLC control, easy to operate.

- Optional dumping device for increased automation.

- Completely detecting the quality of potato raw materials by the roller type inspection testing.

- Adjustable conveying speed during the entire process.

- Using the US Urschel slicing machine, which is fast and having good quality.

- Adjustable slicing shape and thickness of the potato chips.

- There is a de-water device before frying, which saves the heat energy consumption of the fryer.

- Adjustable frying temperature and frying time according to the requirements.

- Safety devices with alarms and shutdowns when the oil is over temperature, the exhaust gas temperature is too high, and the flow pressure difference is abnormal.

- Indirect heating to extend the shelf life of oil and other products.

- Automatically replenishing new oil with the level controller.

- CIP device for quick cleaning of equipment.

- The upper cover of the fryer can be lifted and lowered to facilitate equipment cleaning.

- There are upper and lower limit switches during lifting to increase operational safety.

- The seasoning drum is integrated, safe and hygienic.

- Inspection and delivery before packaging to ensure product quality.

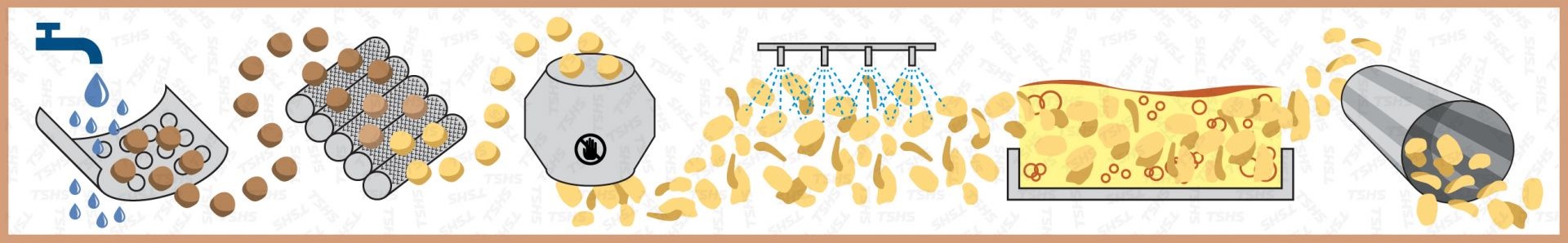

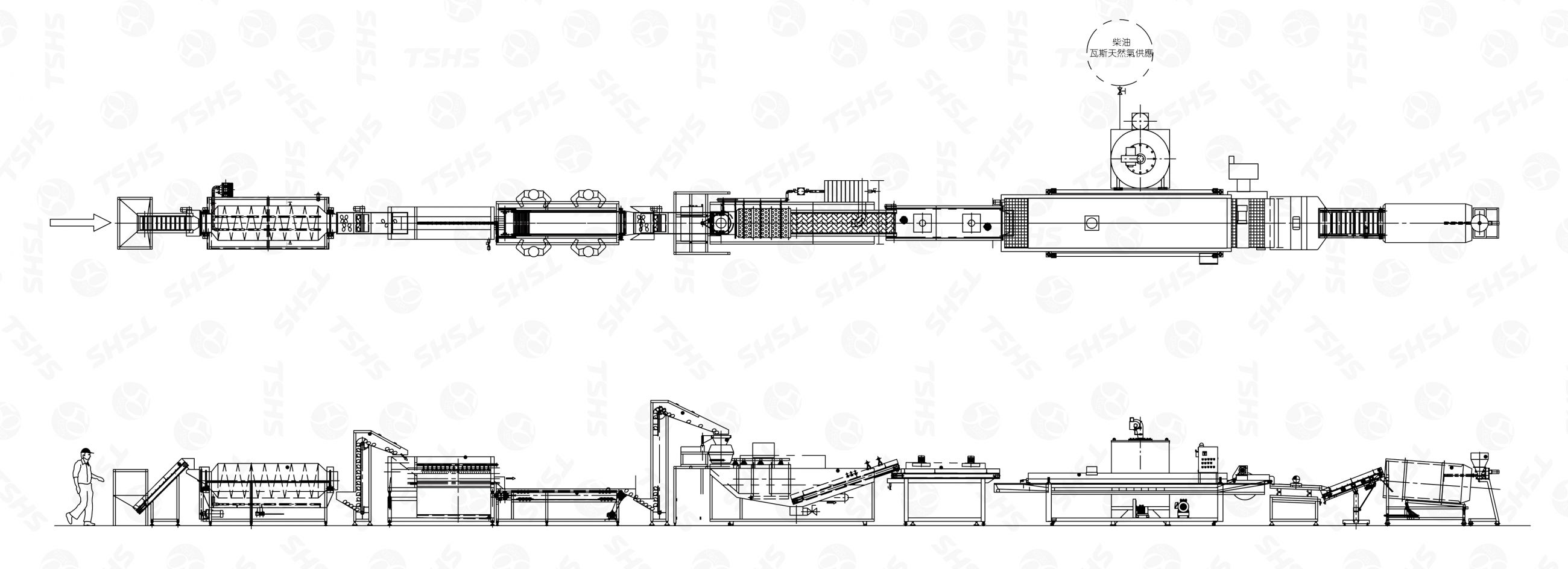

Flow Chart

Feeding → Washing → Peeling → Examine → Slice → Starch Washing → Dripping → Continuous Fryer → Dripping → QC Examine → Seasoning → Cooling → Packing

(This is the basic configuration, please contact us for other special processes.)

SPECIFICATIONS

- Specification: Equipped according to the requirements.

- Function: Sending the product to the next stage of manufacture.

- Horsepower Requirements: 1/2-2HP.

- Features: Can be automated connected to the packaging system according to the requirements.

2. Pouring M/C

- Specification: Length 1500 x Width 1500 x Height 2000 mm.

- Function: The whole box of potato raw materials is automatically poured into the hopper of the production line.

- Horsepower Requirements: 1/2 HP.

- Features: Stably pouring the raw material potato into the hopper one ton per time in a hydraulically driven way, which can greatly economize manpower.

3. Continuous Fine Filter

- Specification: Length 1750 x Width 1410 x Height 1760 mm.

- Conveyor Width: 70mm.

- Horsepower Requirements: 1/4 HP.

- Features: (1) Continuous on-line filtration to simultaneously filter the frying oil in production. (2) The filtering effect can reach 80Mesh to ensure the quality of filtration.

4. De-oil conveyor

- Specification: Length 5000 x Width 1800 x Height 2500 mm.

- Function: Effectively reduce the oil content on the surface and extend the shelf life of the product.

- Horsepower Requirements: 5 HP.

- Features: The excess oil on the product is taken out and matched with the feeding conveyor to achieve the function of continuous operation by using the principle of centrifugal force.

5. Water recovery system: According to the capacity and the requirements, it can achieve the goal of water conservation.

6. Color Sorter

- Specification: Length 3000 x Width 1800 x Height 2000 mm.

- Function: Automatic and continuous elimination of defective products in the production process.

- Features: Using the optical principle, detecting the color difference and quickly shaving the defective product with wind pressure to achieve the online sorting function.

7. Packaging M/C: Can be adjusted according to the requirements and the yield.

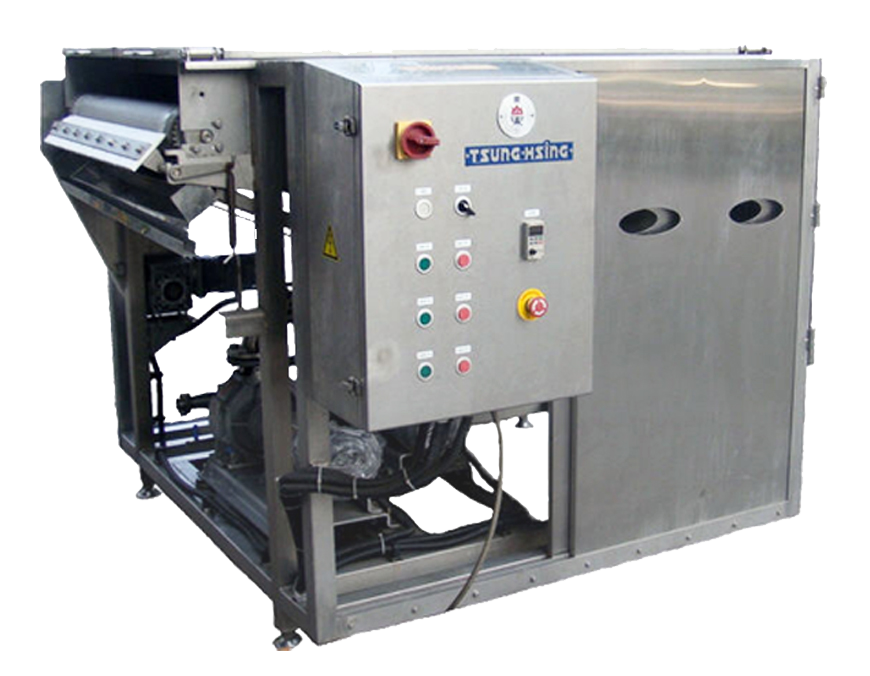

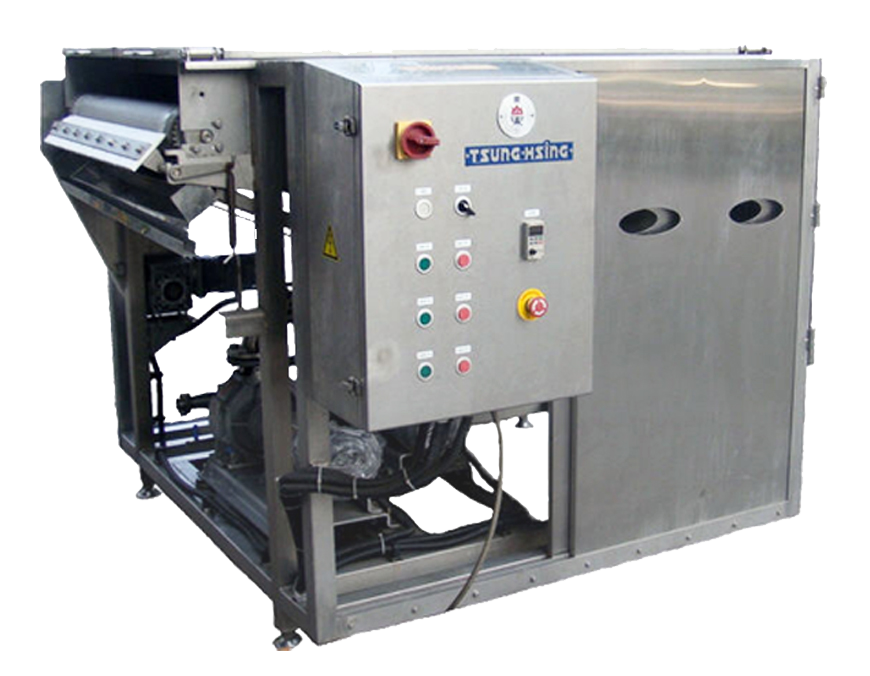

Live Photo

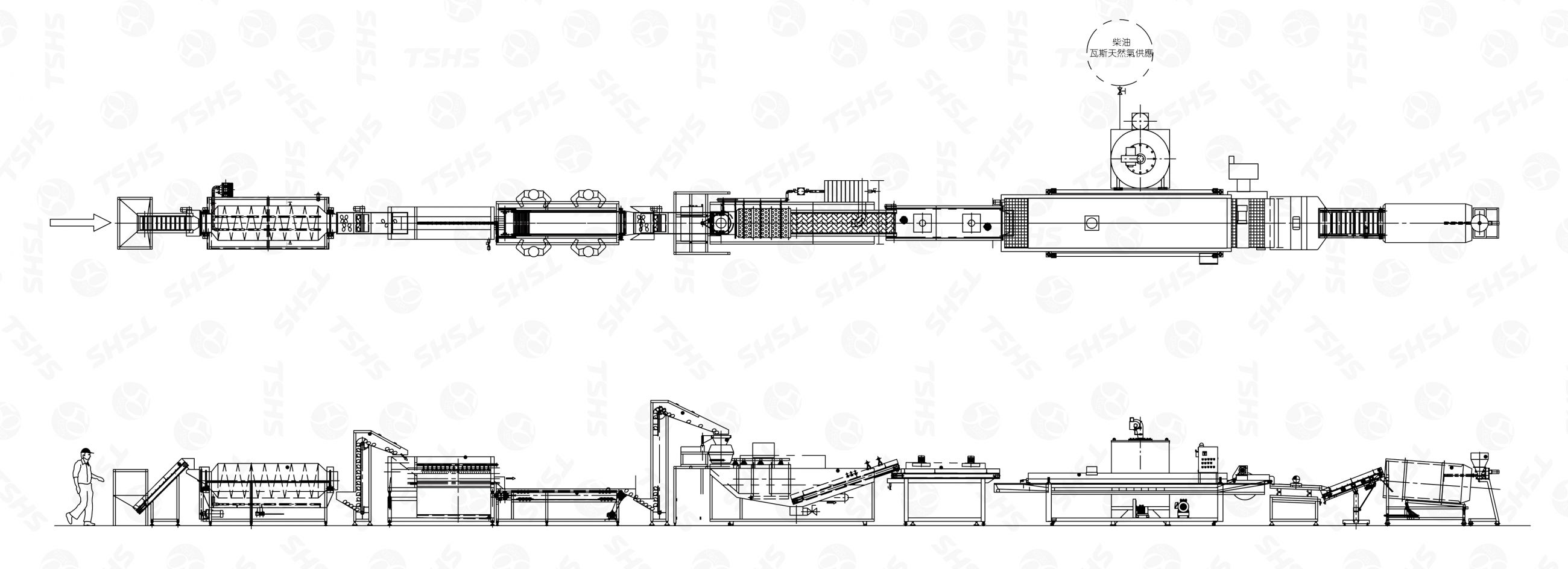

APPLICABLE

LAYOUT

APPLICATIONS

- The Potato Chips Production Line uses fresh potatoes as raw materials, the whole process of washing, peeling, slicing, washing, de-watering, frying, seasoning and other steps to make delicious potato chips, and to be one of the most popular snack food in the world. It’s easy to operate, economizing manpower, made of stainless steel, easy to clean and meets hygienic standards by automatic and consistent production line.