Code : GD 500

Brand name : FAM Stumabo

Price : Contact us

The GD 500 is designed to slice and dice de-boned cooked poultry meat and similar products. It is ideal for cutting fragile and fibrous poultry or fish products while maintaining optimal product appearance and minimising slivering and fines.

The machine can be loaded by hand, laying the product evenly on the infeed belt. Alternatively, infeed and take-off conveyors can be supplied, allowing the machine to form a part of a fully integrated production line.

The GD 500 can be equipped with a cross-blade head for dicing and a single diagonal blade head for slicing.

Applications

The GD 500 is suitable for cutting cooked and / or hot cooked chicken and thigh meat, as well as similar products like tuna.

It can process lightly frozen, marinated, fried, and cooked products.

Features

Guillotine cutting principle does not accelerate or crush the product during the cutting action, greatly improving yield and reducing fines.

Flexibility is maximised by allowing the cut size to be adjusted without the need to change cutting tools.

A hold-down unit keeps the product stable during the cutting operation and can be set according to the product height.

Covers and cutting head can be dismantled quickly for thorough and efficient cleaning.

100% stainless steel or USDA/FDA approved polymeric materials are used in

food contact areas.

Operating principle

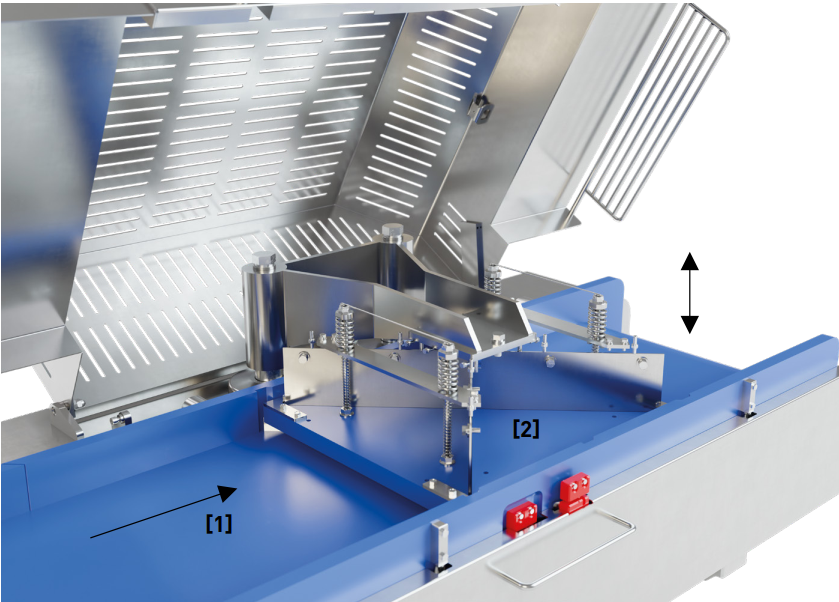

The uncut product is fed onto a conveyor belt [1] which passes under a set of vertically moving guillotine knives [2].

The belt index is synchronised with the vertical reciprocating blade.

The cut size is determined by the distance the belt travels per stroke of the set of knives. This can be adjusted easily with an external handwheel to deliver products ranging in size from 5 mm to 40 mm (1/5” to 1 9/16”).

Technical data

Hotline