Code : CENTRIS 400C

Brand name : FAM Stumabo

Price : Contact us

A compact, versatile cheese shredder with highly accurate cut quality

This high-speed shredder is designed to process medium to high volumes of all traditional cheese varieties and cut shapes. Compact and versatile, it takes up little floor space and can be easily integrated into a production line.

The Centris™ 400C is powered by the innovative, USDA Dairy-accepted Centris SureShred 16-station cutting head which radically improves quality, capacity and yield.

The patented Set & Forget technology guarantees consistent shred dimensions and cut accuracy throughout the production runs without the need for adjustments, even after changing blades and cleaning.

This versatile machine can be supplied with a full range of interchangeable cutting heads.

Applications

The Centris 400C is widely used in the cheese processing industry to shred all kinds of soft, semi-hard, and processed cheeses such as Mozzarella, Emmentaler, Cheddar, and Provolone, as well as analogue and vegan cheese varieties.

A full range of different cut types can be produced, e.g. full or reduced 318 V-, 432 V-and 538 V-shred, oval, wide oval and crescent shred.

The machine can be equipped with grating heads for even greater versatility. A wide variety of grating heads is available to produce fine to coarse particles or granules and different types of special shreds.

Features

The machine is equipped with a 7.5 kW (10 HP) stainless steel motor facilitating easy washdown.

Melting or caking of cheese is avoided by keeping the motor and gearing housed outside of the cutting zone to eliminate heat transfer.

Centris SureShred cutting heads allow slice thickness to be preset, producing uniform shreds and maintaining strict tolerances throughout production runs.

The lightweight stainless steel cutting head is removable and easy to clean.

Operating principle

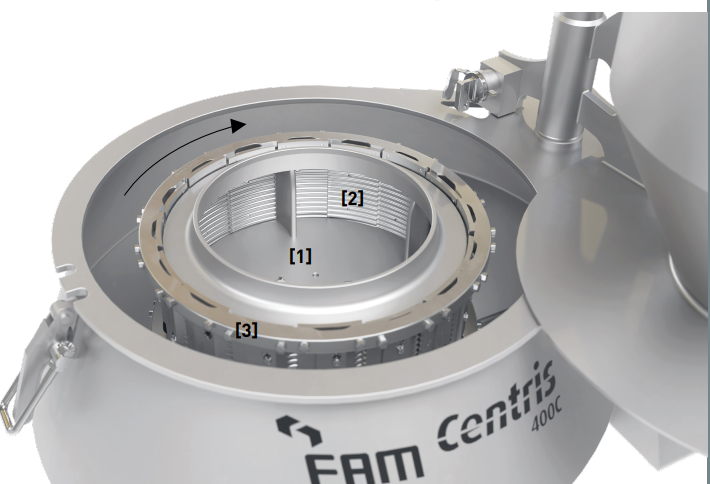

The product is fed through the infeed chute and enters into the cutting compartments of the rotating impeller [1]. There, it is held against the inner surface of the cutting head [2] assembly by centrifugal force.

The cutting head assembly consists of 16 individual stationary cutting stations [3]. Slices or shreds are produced as the product passes each knife in a smooth and uninterrupted manner. Length is controlled by the input product size. The cut product is collected through the central discharge.

Technical data

Hotline