Code : Centris 400

Brand name : FAM Stumabo

Price : Contact us

The Centris™ 400 uniformly slices and shreds a wide variety of vegetables and fruits at high processing output.

It offers food processors precision cutting along with substantial savings in production time and product waste. Its precise and clean-cut quality leads to a longer product shelf life.

This versatile machine can be supplied with a full range of interchangeable cutting heads. The patented 16-station cutting heads accept products up to 130 mm (5 1/8”) and process them very fast and with high accuracy.

The Centris 400 can be integrated into a processing line or used as a standalone machine. Executions with different impeller wheels, infeed chutes and outlet chutes can be selected to accommodate the product shape and size.

Applications

The Centris 400 is widely used in various fields such as vegetable and fruit processing factories, commissary and commercial kitchens, and catering services.

It is suitable for any product that is firm in texture, including carrots, celeriac, potatoes, cabbage and onions, while also providing gentle cutting for more fragile products such as apples, strawberries and coconut.

Numerous different cut types can be produced, e.g. flat, crinkle or V- slices / V-cut, oval shreds, crescent shreds and strip-cuts in many dimensions. Long-shaped products (e.g. carrots, cucumber) can be pre-cut to a specific size to determine the length of the shred.

A complete overview of all shapes is available on request.

Features

Operating principle

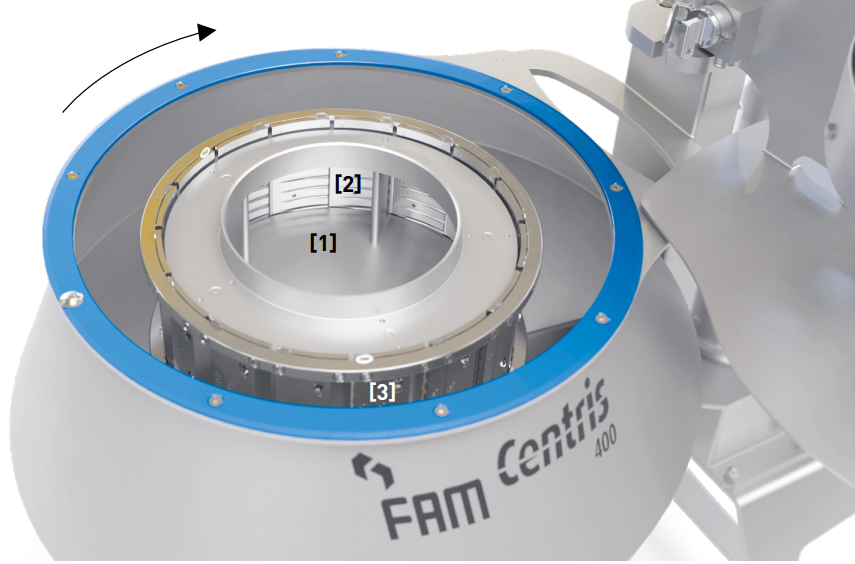

The product is fed through the infeed chute and enters into the cutting compartments of the rotating impeller [1]. There, it is held against the inner surface of the cutting head assembly [2] by centrifugal force.

The cutting head assembly consists of 16 individual stationary cutting stations [3]. Slices or shreds are produced as the product passes each knife in a smooth and uninterrupted manner. Length is controlled by the input product size. The cut product is collected through the central discharge.

Technical data

Hotline