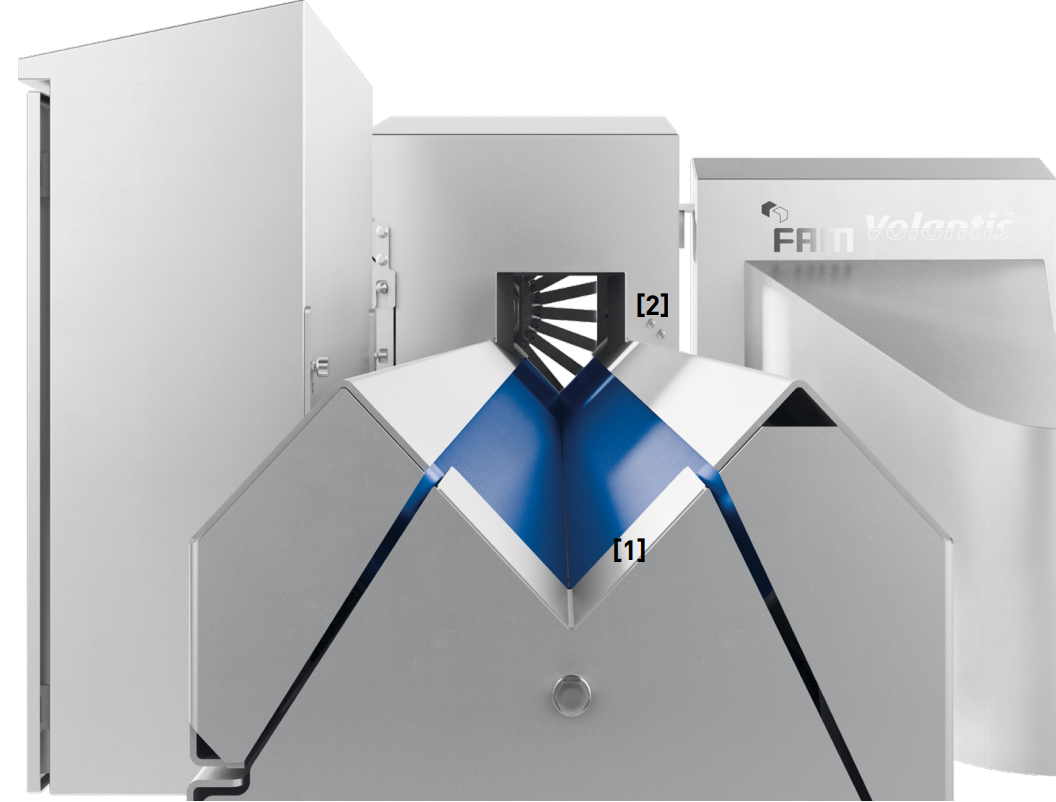

V-belt slicer for optimised productivity

The Volantis™ is designed for accurate transverse slicing of a wide variety of long- and oblong-shaped products. This V-belt slicer guarantees high quality cuts at medium to high volumes. High knife speed and a unique cutting method combine the production of uniform slices with a smooth surface and a minimum of breakage and ragged ends. The Volantis offers food processors precision cutting along with substantial savings in production time and product waste. Its clean cut quality leads to longer product shelf life for fresh-sliced products. The Volantis can be supplied with a large variety of cutting tools for more product differentiation (e.g. flat slice, crinkle slice, julienne, halving and spears).

Applications

The Volantis is designed for precision cutting of long-shaped and oblong vegetables with diameters up to 115 mm (4 17/32”) with extreme precision. Typical applications include cucumbers, carrots, zucchini, green beans, gherkins, okra, celery, potatoes and firm head varieties of lettuce such as iceberg and radicchio. For compressible loose-leaf lettuce varieties like frisée, oak leaves and rucola, and other leafy-type vegetables such as spinach and radish greens, the Volantis can accept products up to a size of 160 mm (6 19/64”).

Features

• The two-metre long infeed optimises the orientation of the product, aligning it perfectly to prevent it from tumbling while it is being fed into the slicing wheel.

• Programmed speed settings for the slicing wheel and V belts facilitate maximum cut quality at the highest capacity.

• Excellent hygiene and cleaning access, limited wear parts, easy-to-replace feed belts and increased output combine to reduce the total cost of ownership (TCO) and ensure fast return on investment.

• The compact touchscreen provides a simplified, easy-to-follow operator interface for quick setup and product changeover.

Operating principle

The product slides onto two conveyor belts positioned in the V-shaped feed channel [1] which ensure automatic positioning and highspeed transport of the product to the cutting wheel. The slicing wheel (2), in combination with the selected or programmed speed on the feed belt and slicing wheel VFDs, maintains the speed of the product while it is being sliced. This eliminates the need for motorised hold-down belts for most products. The thin, tensioned knives of the cutting wheel act as spokes and support the rim. The knives are twisted to create a uniform pitch from the hub to the rim. It is this pitch that maintains the continuous speed of the product while it is being sliced. The conveyor belt speed is synchronised with the cutting wheel speed to ensure correct advance of the product per revolution of the cutting wheel.

Technical data

Hotline